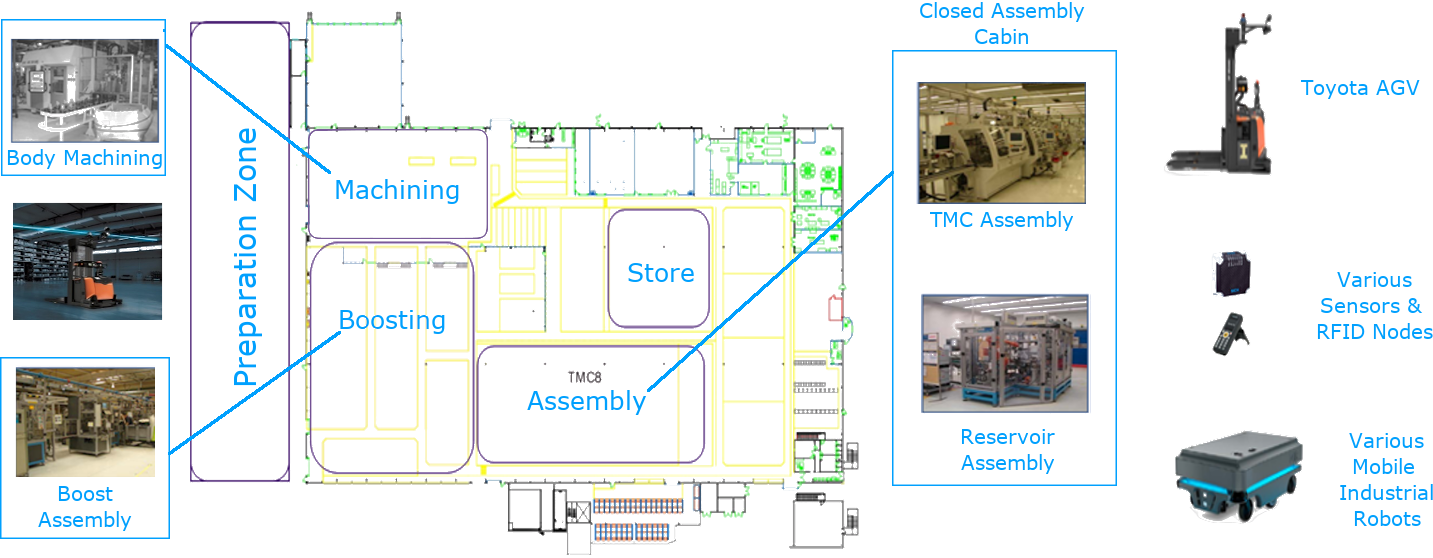

The first Industry 4.0 Living lab will validate the IoT-NGIN federation framework in real-life applications implemented at BOSCH’s facilities (Trial#4) in Aranjuez, Madrid.

In Aranjuez facilities, BOSCH manufactures a range of car electromechanical brake boosters. Automated Guided Vehicles (AGVs) are widely used to transport materials from the Preparation Zone to the Production Zone (Machining, Boosters, Assembly). In the IoT-NGIN living lab, Toyota AGVs and various Mobile Industrial Robots which differ in shape, size, and operation will be utilized. The AGVs are equipped with safety systems, such as reversing sensors and front safety sensors, which are able to perform emergency stops. However, they cannot be effective if obstacles are permanently in motion, such as human workers, while the sensors have limitations in detecting other types of AGVs, in particular when there is no “visual” contact with the object. To ensure human workers safety and driven Forklifts (from AGVs and the surrounding factory equipment), and to avoid collisions, a user-aware and semi-autonomous IoT system is required, which acts in real-time and solves performance challenges prioritizing human-centered safety.