The digitalization effort of industry 4.0 aims for more efficient utilization of data throughout the different stages of a product’s life cycle and value chain. A good example of this are CAD-models. CAD-models are typically used in the design and manufacturing stages, however these accurate models could just as well be utilized in other parts of the value chain, such as marketing, sales, and maintenance related operations. For example, Augmented reality (AR) applications offer a good way to mine additional value out of the existing CAD-models. Having an accurate virtual model that can be used to create interactable applications can be a great tool for sales or maintenance personnel.

One of the main issues in utilizing CAD-models throughout the value chain is how to make the model accessible for applications and end users. Shipping a CD-ROM containing the CAD-model together with product itself is not in the spirit of industry 4.0 or the modern times of digitalization. Generally speaking,the availability of data and digital features is closely related to the concept of digital twins. Instead of shipping a static copy along with the product, the CAD-model should be made available via the product’s digital twin. Typically, digital twins nowadays involve cloud hosted data and services that require registration e.g. by using the serial number of the product in question. These types of proprietary digital twin solutions typically suffer from a lack of standardization and interoperability in terms of their interfaces and usage. The further improvement of the digital twin concept, e.g. via standardization efforts, is important in order to efficiently leverage existing data at different stages of the value chain, such as CADmodels. This is well acknowledged in existing standards such as the Asset Administration Shell (AAS) and the Web of Things model (WoT). Similarly, in the IoT-NGIN project, the digital twin concept is further developed by augmenting it with meta-level information in the form of the so-called ‘semantic twin’ component.

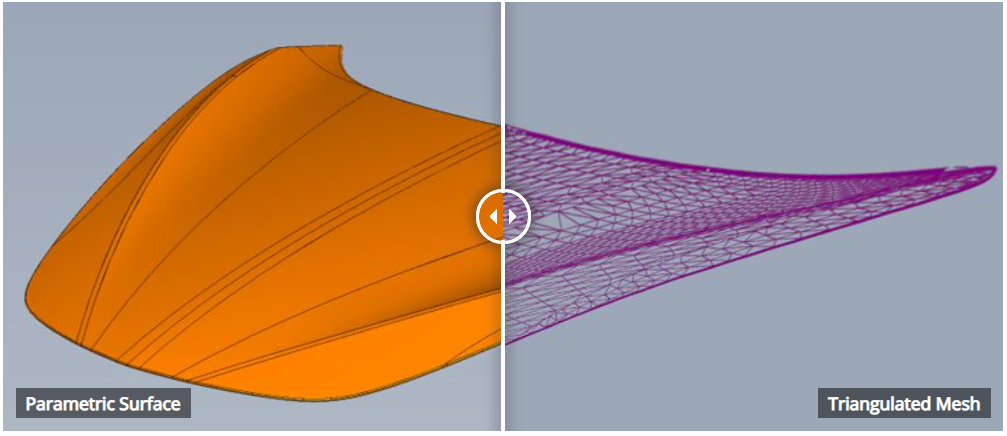

Another issue in utilizing CAD-models involves the format of these CAD-files and their use in application development. In CAD-files solids and surfaces are often defined using curves and mathematical functions.However, typically graphics cards and computer programs doing real-time rendering are optimized to handle surfaces that are defined using triangular meshes. For example, AR & game development engines such as Unity and Unreal Engine are designed to work with triangular meshes. In order to import a CADmodel to such an application environment, the triangular meshes need to be computed in a process called tessellation. The resulting meshes closely approximate the surfaces defined in the CAD-model. 1

Many existing software packages and plugins for importing CAD-models into AR application development environments exist: Pixyz for Unity, and Datasmith for Unreal engine. In IoT-NGIN, a repository of software components, assets, scripts, and tools related to AR platforms such as Unity and Unreal engine will be collected and maintained. The goal is to allow users and things to connect in new ways, e.g. by creating augmented and mixed reality environments via the use of CAD-models.

References